Density Of Hydrogen Kg M3

The problem of hydrogen storage

HYDROGEN has long been considered a transformative applied science for the energy sector, as it fulfils the main requirements of a clean and sustainable energy vector. It is abundant in the Universe and on World, has the highest energy density on a mass footing of whatever chemical fuel, and can be easily converted between different forms of energy. For all of these reasons, hydrogen is considered i of the all-time options for decarbonising the transport sector, which is however almost completely reliant on fossil fuels.

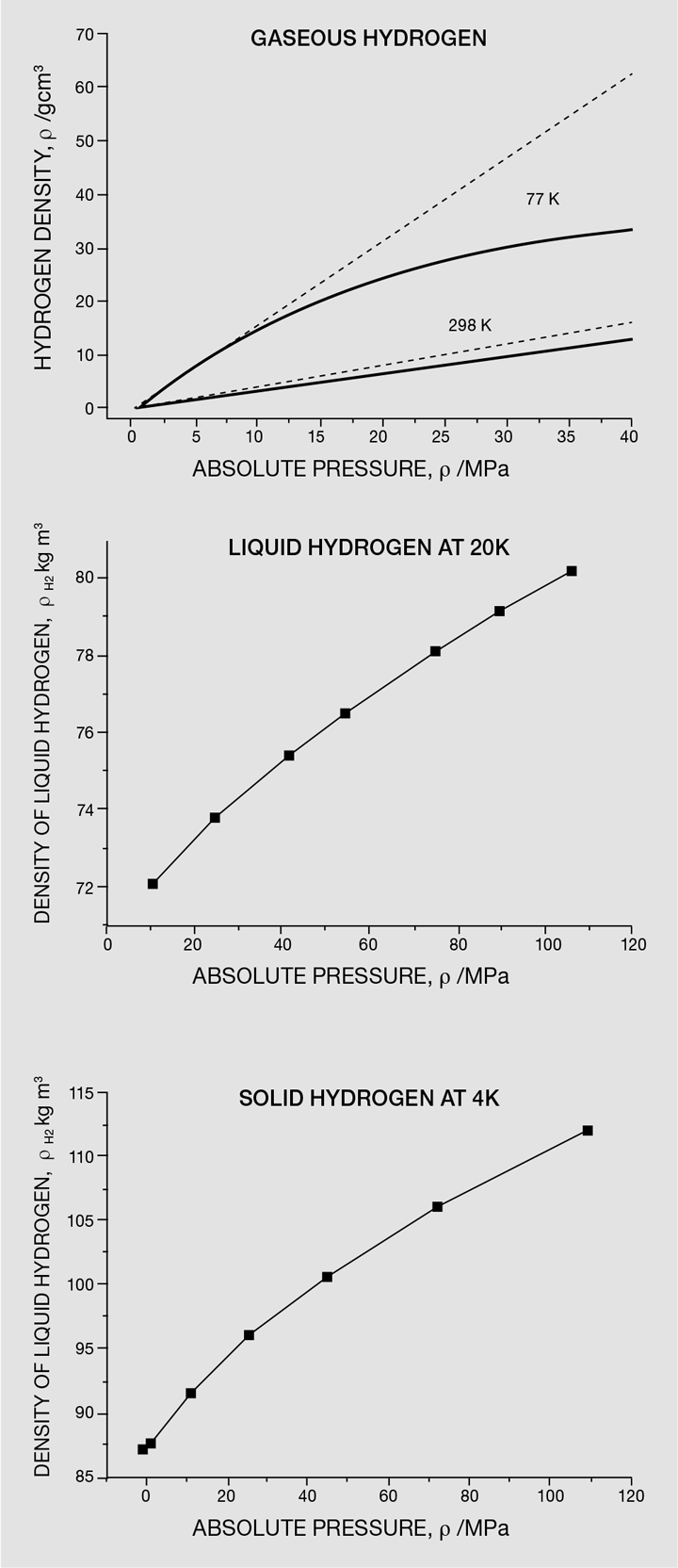

A number of technical issues nevertheless prevent the widespread utilise of hydrogen every bit an free energy vector, at the top of which is how to store hydrogen in an affordable, sustainable and condom manner. This difficulty comes from the concrete backdrop of hydrogen – hydrogen is the first element in the periodic table and it is the lightest. Free hydrogen exists as a diatomic molecule (H2) and has a density at standard temperature and force per unit area (0 °C and 0.1 MPa) of around 0.09 kg/grand3 [1], which is significantly less than air (1.three kg/10003). Its normal boiling and melting points are effectually -253 °C and -259 °C, respectively, and even equally a liquid or a solid, information technology has extremely low densities. Liquid hydrogen at -253 °C and 0.one MPa has a density of 71 kg/chiliadthree [2] and solid hydrogen at -259 °C and 0.ane MPa has a density of 88 kg/miii [three]. Hydrogen has some peculiar properties, including the fact that it can be compressed equally a liquid and every bit a solid. Effigy 1 shows the density of hydrogen in the gaseous, liquid and solid state at increasing pressures.

Figure 1: Density of gaseous, liquid and solid hydrogen at -196.15°C (77 1000), 24.85°C (298K), 253.15°C (20K) and -269.15 °C (4K), respectively. Dashed lines in gaseous hydrogen represent platonic gas densities while solid lines are real gas densities. Data taken from [1–3].

Hydrogen has a very large free energy density on a mass ground, but the challenge is to improve on its volumetric energy density. To achieve this, a number of dissimilar technologies have been proposed, with the main goal being to design a hydrogen storage system that is affordable, sustainable, safety, and one in which hydrogen tin can be easily and quickly charged and discharged. Enquiry in this surface area has been driven by targets created past the United states of america Department of Energy for hydrogen storage systems in automotive applications [iv]. These targets look at a number of practical requirements, including gravimetric and volumetric densities, delivery temperatures and pressures, number of cycles, efficiencies, cost, charging and discharging rates, safety, and others. To engagement, no textile or organisation unequivocally addresses the majority of the different requirements.

Nether pressure

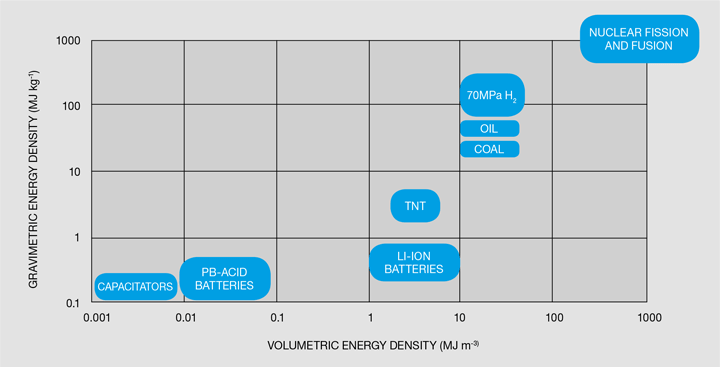

The most conventional style of storing hydrogen and the current land-of-the-art in the chemic industry is to store hydrogen every bit a gas following pinch. In vehicular storage systems, hydrogen is commonly stored in compressed hydrogen cylinders at 35 or 70 MPa. For comparison, a typical tyre in a car has a pressure of 0.23 MPa! The hydrogen storage cylinders are classified in 4 dissimilar types: stainless steel or aluminium (type I), fibre-resin composites with thick metallic lining (type Ii), fibre-resin composites with fully wrapped metal liners (type III) and polymeric liners fully wrapped in fibre resin composites (type IV), with volumes usually ranging from 0.050–0.200 kthree [5]. Blazon IV cylinders are the well-nigh common selection, with a polymeric liner such as high-density polyethylene (HDPE) used as the gas permeation barrier. Information technology is of import to recall that hydrogen tin easily permeate most materials, which is why properly lining the cylinders is so of import. 1 of the master problems with compression of hydrogen is that it carries a large energy penalty – the energy used in compressing hydrogen to 35 MPa is 14.5 MJ per kg of hydrogen, and if compressed to 70 MPa, then it is 18 MJ per kg of hydrogen [6]. This would hateful that, if stored at 70 MPa, about 15% of the energy contained in the hydrogen is spent compressing information technology! All the same, compressed hydrogen is the engineering of pick for the chemic industry and for most of the current commercial hydrogen fuel prison cell vehicles. Compressed hydrogen storage has good volumetric and gravimetric energy densities in comparison with other energy storage methods, as seen in Effigy 2.

Effigy ii: Volumetric and gravimetric energy densities of unlike energy storage methods or sources. Adapted from Zuttel et al [7]

Cool downwardly

Some other conventional storage method to achieve higher volumetric densities is to liquefy hydrogen. The problems associated with liquefaction are that hydrogen's normal humid point is –252.ix °C (twenty.2 K), which is a very difficult temperature to accomplish and maintain. As a liquid, hydrogen is typically stored at 20.0 Yard and with pressures ranging from 0.1–one MPa. In this country, hydrogen has a volumetric density of 70.3 kg/m3 [vi], which compares to volumetric densities of 23.ii kg/thousand3 and 39.0 kg/one thousandiii for compression at room temperature at 35 and lxx MPa, respectively [i]. Despite the good hydrogen volumetric densities, liquid hydrogen has some issues, at the top of which is boil-off. Information technology is very hard to completely insulate the storage system, so some hydrogen volition heat up and boil off, creating high pressures in the tank, which has to be depressurised past venting the hydrogen. This is an even bigger result if the tank is left fallow for long periods of time. In addition to boil-off, in that location is also a big energy penalization with liquefaction of hydrogen, which can be as much as 36 to 47 MJ per kg of hydrogen, which is effectually 30 to 40% of its lower heating value, making liquefaction of hydrogen a very energy intensive method [6].

How about a mixture of the two?

Due to shortcomings in both liquid and compressed storage, other alternative physical storage methods are being investigated. One of these is cryogenic pinch of hydrogen, which is a combination of compression and liquid storage, and tries to mitigate the issues that plague both methods by avoiding loftier pressures and very low temperatures. The main advantage of cryogenic pinch is its flexibility, as it tin can operate at temperatures every bit low as 20 Thousand (-253°C) and at pressures up to 25 MPa, with typical operating weather condition between 20 and 60 K (-253 °C and -213 °C, respectively). Having hydrogen both compressed and at cryogenic temperatures creates a bigger remainder‑of-found, merely hydrogen gravimetric capacities for whole systems can be as loftier as 45.0 kg/m3 [8]. Much of the work done on cryogenic pinch has originated from research in the US Department of Energy laboratories, and some motorcar manufacturers such as BMW are looking into the technology [ix].

What about reacting hydrogen with something?

The issues surrounding compressed and liquid storage, specially the ones associated with costs and rubber, have led to the development of other storage alternatives. One surface area that has seen considerable research is chemical storage of hydrogen. In chemical storage, the hydrogen molecule dissociates and reacts with a material, forming a hydride. Most of the issues associated with storing hydrogen as a hydride are related to dehydrogenation, which is difficult every bit it requires loftier temperatures, and reversibility, which can be problematic if the storage textile is used over many cycles [half-dozen, x]. Hydride materials that accept been suggested as hydrogen storage materials include palladium hydride (PdH), magnesium hydride (MgH2) and magnesium borohydride Mg(BH4)2. Hydrogen can also be stored through other routes, including hydrogenation of organic molecules.

The ammonia economic system

Some other possibility is to have reward of the current infrastructure available for liquid fuels and use ammonia as a hydrogen carrier. Ammonia has high volumetric and gravimetric hydrogen densities, tin exist stored as a liquid at moderate pressures and tin exist decomposed to release hydrogen in a catalytic reaction [11]. The main disadvantages of using ammonia as a hydrogen carrier are related to its toxicity and reversibility, as trace amounts of ammonia are found in the hydrogen later it decomposes [11]. The ammonia needs to be decomposed to release the hydrogen, which is normally done at loftier temperatures in the presence of a goad, with much contempo research focussed on low temperature (<300°C) catalytic decomposition of ammonia. In addition to its high densities, ammonia has the advantage of only releasing water and nitrogen when decomposed to release the hydrogen.

Storing hydrogen in nanomaterials

Hydrogen can also be stored through adsorption in a porous material. Adsorption will be very familiar to chemical engineers, as it is widely used in the chemical industry for gaseous separations in adsorption columns. Adsorption of hydrogen is considered an attractive pick, as information technology can offer good densities at moderate pressures and temperatures [half-dozen]. In adsorption, the hydrogen molecule does not dissociate and does not react with the substrate fabric. Hence, hydrogen adsorption typically has fast kinetics and is completely reversible. The operating conditions are milder than other forms, as it is usually done at 77 K and in the 1 to v MPa range. Storage of hydrogen through adsorption is highly dependent on the type of cloth. Ideally, the textile has a very high surface areas, as gravimetric hydrogen storage correlates with available surface expanse, and pores below 1 nm, equally these have the highest free energy of interaction with the gas [6]. In addition to this, it needs to be depression density, depression cost, and should possess adept mechanical and thermal properties.

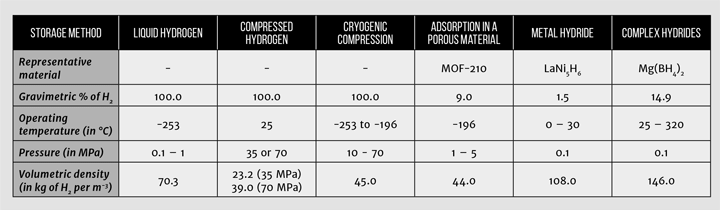

Many interesting developments in synthetic chemical science have occurred in the terminal five years, peculiarly in the synthesis of highly porous materials with tuneable properties. One excellent example are metallic-organic frameworks (MOFs), crystalline materials made from metal centres and organic linkers. Examples of high surface-area metal organic frameworks that have been proposed as hydrogen storage materials include NU-100 [16] and MOF-210 [xiii], both of which take surface areas in excess of 6,000 mtwo/g which is almost the area of the Wembley pitch in one gramme of material! Other recently discovered loftier-surface area materials include porous polymers and novel activated carbons, which tin have surface areas in excess of 3,000 mtwo/g [17, 18]. The different hydrogen storage technologies are presented in Table 1, with gravimetric and volumetric densities, and operating weather condition.

Table 1: Dissimilar hydrogen storage technologies, with operating weather and gravimetric and volumetric hydrogen densities. With data from [i, 12-15]

With a pinch of salt

In addition to applications in mobile vehicles, hydrogen has too been considered for grid-scale energy storage. In this context, as the storage is ordinarily stationary, gravimetric and volumetric free energy densities are less important, and hydrogen is stored hole-and-corner in common salt caverns or depleted oil and gas fields. Hugger-mugger hydrogen storage is currently beingness used in the UK. Examples include the Teesside region, where 3 salt caverns are licensed for operation, each with lxx,000 thousandiii. The storage occurs at 4.v MPa at a depth of 400 yard, and the caverns are operated by SABIC, which used information technology to distribute hydrogen to chemical plants in the area [19].

The storage puzzler

In the transport sector, rather than a competing engineering, hydrogen has been considered an excellent complement to battery electric vehicles, since it can be used as a range extender, equally batteries start to go uneconomic with big sizes [20]. A hybrid solution that integrates fuel cells with battery systems seems to be the safest bet at the moment for decarbonising the transport sector, except for very small cars in urban areas that take low-cost batteries [20]. In order for hydrogen to be feasible as a fuel in mobile applications, advisable storage systems need to exist designed and adult, focussing on affordability, safety and sustainability. While recent studies have shown potential in some technologies, there is still no clear cutting answer to the hydrogen storage trouble, with industry opting at the moment to use compressed hydrogen cylinders in commercial vehicles, which have safe issues and incur in large energy penalties. In that location is plenty of room for improvements and innovations in this fascinating topic, and many aspects where chemical engineers tin add together value. The transport sector is ane of the sectors virtually dependent on fossil fuels, so it is imperative that we find make clean and sustainable solutions that tin can be implemented at a global scale in this sector. Despite all the technical problems nonetheless present with hydrogen, in that location are many advantages of using it every bit an energy vector, and it is very likely that hydrogen volition be part of a global futurity energy mix.

This is the 10th article in a serial discussing the challenges and opportunities of the hydrogen economic system, developed in partnership with IChemE'due south Clean Energy Special Interest Group. To read more from the series online, visit the serial hub.

References

- Leachman, JW, et al, Primal Equations of Land for Parahydrogen, Normal Hydrogen, and Orthohydrogen. Journal of Physical and Chemical Reference Information, 2009. 38(3).

- Johnston, HL, WE Keller, and AS Friedman, The Compressibility of Liquid Normal Hydrogen from the Boiling Point to the Critical Point at Pressures up to 100-Atmospheres. Periodical of the American Chemical Society, 1954. 76(6): p1482-1486.

- Silvera, IF, The Solid Molecular Hydrogens in the Condensed Phase - Fundamentals and Static Properties. Reviews of Mod Physics, 1980. 52(2): p393-452.

- The states Department of Energy. DOE Technical Targets for Onboard Hydrogen Storage for Light-Duty Vehicles. Bachelor from www.energy.gov/eere/fuelcells/doe-technical-targets-onboard-hydrogen-storage-light-duty-vehicles. Accessed November 2018.

- Barthelemy, H, Hydrogen storage - Industrial prospectives. International Journal of Hydrogen Energy, 2012. 37(22): p17364-17372.

- Eberle, U, Felderhoff, M and Schuth, F,Chemic and Physical Solutions for Hydrogen Storage. Angewandte Chemie-International Edition, 2009. 48(36): p6608-6630.

- Zuttel, A, et al, Hydrogen: the future free energy carrier. Philosophical Transactions of the Royal Lodge A: Mathematical Physical and Engineering Sciences, 2010. 368(1923): p3329-3342.

- Ahluwalia, RK, et al, Technical assessment of cryo-compressed hydrogen storage tank systems for automotive applications. International Journal of Hydrogen Energy, 2010. 35(9): p4171-4184.

- BMW Group. Press release: Commencement hydrogen station with two types of refuelling technology. Available from www.press.bmwgroup.com. Accessed November 2018.

- Weidenthaler, C and Felderhoff, M,Solid-state hydrogen storage for mobile applications: Quo Vadis? Free energy & Environmental Science, 2011. 4(7): p. 2495-2502.

- Klerke, A, et al, Ammonia for hydrogen storage: challenges and opportunities. Journal of Materials Chemistry, 2008. 18(20): p2304-2310.

- Chlopek, Yard, et al, Synthesis and properties of magnesium tetrahydroborate, Mg(BH4)(ii). Journal of Materials Chemistry, 2007. 17(33): p3496-3503.

- Furukawa, H, et al, Ultrahigh Porosity in Metal-Organic Frameworks. Science, 2010. 329(5990): p424-428.

- Orimo, SI, et al, Complex hydrides for hydrogen storage. Chemic Reviews, 2007. 107(10): p4111-4132.

- Sandrock, 1000, A panoramic overview of hydrogen storage alloys from a gas reaction point of view. Journal of Alloys and Compounds, 1999. 293: p877-888.

- Farha, OK, et al, De novo synthesis of a metal-organic framework material featuring ultrahigh area and gas storage capacities. Nature Chemistry, 2010. 2(11): p944-948.

- Strobel, R, et al, Hydrogen storage by carbon materials. Periodical of Power Sources, 2006. 159(2): p781-801.

- Svec, F, Germain, J and Frechet, JMJ,Nanoporous Polymers for Hydrogen Storage. Small, 2009. five(x): p1098-1111.

- Leeds City Gate. H21. Available from world wide web.northerngasnetworks.co.uk/wp-content/uploads/2017/04/H21-Report-Interactive-PDF-July-2016.compressed.pdf. Accessed November 2018.

- Offer, GJ, et al, Techno-economic and behavioural analysis of bombardment electrical, hydrogen fuel prison cell and hybrid vehicles in a future sustainable road transport system in the United kingdom of great britain and northern ireland. Free energy Policy, 2011. 39(4): p1939-1950.

Density Of Hydrogen Kg M3,

Source: https://www.thechemicalengineer.com/features/the-unbearable-lightness-of-hydrogen/

Posted by: martinezroas1985.blogspot.com

0 Response to "Density Of Hydrogen Kg M3"

Post a Comment